|

|

|

| |

|

|

|

|

|

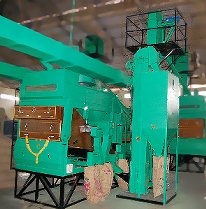

The

main function of this machine is clean the seeds

received from production site before it is fine

cleaned The Seeds and grains have lot of dirt, inert

matter, reject material, stones, dust and plant

parts when it is harvested and threshed.

To clean it

partially it is fed to Per Cleaner where it is

cleaned at high speed separating all unwanted

material like light chaff, kadi, katli, sand, soil,

infested seeds, immature seeds, under size seeds,

over size seeds etc. so that the Fine Cleaner can do

its basic function of Fine cleaning and proper size

grading. |

| ^ |

|

|

|

|

The

function of this machine is to clean and grade the

seeds and grains. Per cleaned seeds are further

cleaned and properly size graded by Fine Cleaner.

Only good quality seeds can give good crop and

similarly good quality grains that can be used to

produce food material for human consumption.

To make

this possible, it uses the principle of screening

and airflow to remove the unwanted material. The

machine is electrically powered to operate at

desired speeds while maintaining quality. |

^ |

|

|

|

|

It

is a very useful machine to separate seeds or grains

of same size but different in weight.

Usually seeds

or grains do not develop in a uniform manner and

hence some seeds are light and some heavy in weight.

Non-uniform developed seeds do not germinate

properly and thereby reduces the output of the farm.

The gravity separator separates such seeds into

three fractions, uniformly heavy seed, rejects seeds

and moderately developed seeds. The machine blows

air through a mass of seed traveling from one end of

the deck to another. The deck, a wire mesh bed

vibrates the seed and causes stratification of seed

into light, medium and heavy material.

An AC variable Frequency drive with an AC motor

controls the deck vibration so that proper vibration

of seed separates the heavy from light accurately. |

|

^ |

|

|

|

|

The

function of this machine is to remove stones from

the grains and seeds. When seeds and grains are

harvested in the field, usually mud particles and

small stones get mixed and form almost 5 to 7 per

cent by weight.

Accurate setting of this machine can

remove most of the stones with ease. Machine is

powered electrically and driven by a motor.

An AC variable Frequency drive with an AC motor

controls the deck vibration. |

|

^ |

|

|

|

|

Vertical bucket elevators are required to connect

the individual machines. The elevator feeds the

machines continuously.

They are powered by geared

motors so that required feeding is always

maintained. These are fitted with single belt on

which PVC Bucket are fixed to feed the material and

avoid seed damage. |

|

^ |

|

|

|

These are special elevators where we have to lift

two different grades of material and feed at

different places. In this machine two belts are

provided with PVC bucket and have two way discharges

valve so that material can be delivered at desired

place by spout pipe. |

^ |

|

|

|

|

This is the Star product of our group. Nobody in

India is manufacturing the machine other than us.

This machine has almost 20,000 Stainless Needles and

does a wonderful job of separating cotton seeds.

Cotton is a cash crop of the Indian agriculture.

Many farmers around the country sow cotton crop and

hence quality of the cottonseed is most important.

Needle Sorter is one of the important machines in

cotton seed processing. It separates the “Pin Hole”

seed and cut seed from the lot of averagely

processed seeds. The removal of pin hole seeds and

cut seeds enhance the quality of the processed seed.

Pin hole seed and cut seed form almost 5% to 7%

quantity in the seed lot. The machine is also used

for Okra seed cleaning.

Now, we are working on a project where the Needle /

Pin Sorter will be used to clean the Sales Return

Seeds and by using a Bulk packing machine it will be

bulk packed before stacking. |

^ |

|

|

|

|

These are different capacity bins for storage of

material fed by elevator so that even feeding is

ensured on Gravity / Destoner deck for proper

separation.

Also a final Packing bin is provided in

complete Plant layout where final finished seed is

stored before it is stored in bag in storage godowns.

|

^ |

|

|

|

|

This system is given to extract dust coming seed

received from fields due to mud particles. There are

few points in complete layout of a plant from where

we can collect the dust generated and send it

outside plant, making the plant dust free. |

^ |

|

|

|

|

For

De linted cotton seed / one year old Bajra seeds

this machine is very useful for cleaning and

removing the light immature seeds, dust, infested

seeds. Very low power consumption and best result is

achieved in this machine. |

^ |

|

|

|

|

This machine is developed by our company to extract

the seeds from ripened Tomato fruit. The fruits are

fed in the hopper which feds it through auger to

crusher assembly. Fruit is crushed and upper pulp is

separated by rotating blade in upper drum from juice

whit seeds. The juice with seed passes through SS

perforated round sheet in to lower drum. Here also

there is round SS perforated sheet to separate the

juice and seed from each other.

Machine has adjustments for crusher depending upon

fruit size to crush it perfectly.

All main contact parts in SS with heavy supporting

structure and separate mounting structure for 5 HP

Hand operated Diesel Engine. Foundation for

electrical motor is also provided on MS structure

for operating machine by electrical motor in case of

availability of electrical power. Electrical motor

can be provided if required at separate additional

cost.

Cleaning of machine is also very easy. Just open

upper and lower drum outer covers. Open side Flanges

fixed in 3 nuts for upper and lower drum. Machine is

ready for cleaning. Pour water from hopper end and

clean the machine.

Capacity- 2 to 3 Ton per hour. |

|

^ |

|

|

|

|

This is a Vertical Model Dryer in which the surface

moisture given to seeds during the seed coating /

treatment is removed and seeds are brought to

original moisture content level before seed coating/

treatment. No Overheating is done to avoid the

germination % loss of seeds. |

|